In industrial maintenance and repair—especially in the demanding mining industry—there’s a critical need for reliable, high-performance materials. Whether you’re dealing with heavy machinery, critical structural components, or equipment exposed to extreme conditions, the right epoxy systems can make all the difference.

Copps Industries offers a full lineup of epoxy products designed to meet the toughest challenges, providing durability, rapid strength development, and exceptional protection against erosion, corrosion, and wear.

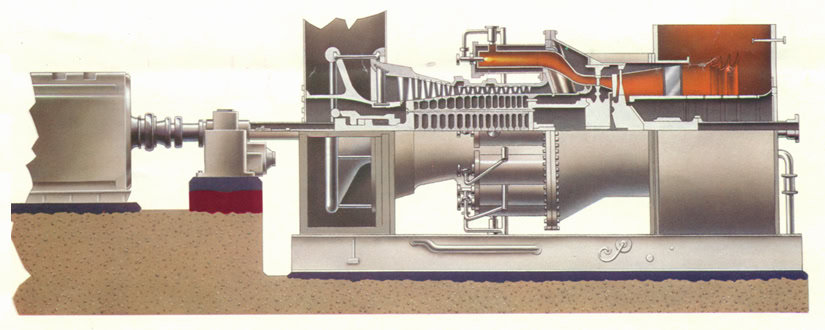

Here, we’re looking at four standout products from our lineup: REDBAC Deep Pour 3CE Grout, Maximum Performance Pumpable Grout, Armor Plate High-Performance Brushable Ceramic, and Armor Plate – Steel – Fast. From deep grouting large machine bases in mining operations to protecting pumps and impeller blades, these epoxy systems are engineered to deliver unmatched performance and longevity.

REDBAC Deep Pour 3CE Grout (K-028)

REDBAC Deep Pour 3CE Grout is a three-component, 100 percent solid epoxy resin system designed for pours up to 8″ (20.3 cm). Deep Pour 3CE offers rapid strength development, excellent flow characteristics, and minimal shrinkage. It flows into spaces under machines, fills completely before solidifying, and is self-leveling. It will survive impact and vibration equal to reinforced rubber materials and will not de-laminate under the most severe shock loads.

Common applications for Deep Pour 3CE include:

- Deep grouting of large machine bases

- Setting large pumps

- Setting large sole plates

- Deep repairs in foundations

- Use as a concrete alternative for critical machine settings

Maximum Performance Pumpable Grout (K-027)

Maximum Performance Grout is a two-component, 100 percent solid epoxy system designed for wet, underwater, high strength, and rugged, durable service. Its low component viscosity and mixed viscosity allow for efficient, problem-free meter mixing and pump dispensing into voids from 1/2″ up to 2″. Maximum Performance Grout delivers high compressive strength in extreme conditions, making it ideal for water exposure applications, including quoin and miter blocks for lock miter gates. The low viscosity and thixotropy of Maximum Performance Grout allow it to flow into narrow spaces at a rapid rate, shortening application time and assuring solid foundation support.

Common applications for Maximum Performance Grout include:

- Gyratory bottom shell placement

- Large mining cone replacement

- Pump bases

Armor Plate High-Performance Brushable Ceramic (K-096)

HP Brushable Ceramic is a two-component, high-performance ceramic-filled coating system designed for sealing, protecting, and repairing surfaces subject to high wear. HP Brushable Ceramic allows you to seal and protect equipment exposed to erosion and corrosion effectively. This solvent-free epoxy system has excellent chemical resistance.

Common uses for HP Brushable Ceramic include:

- Protect pump casings, impeller blades, gate valves, water boxes, and fan blades

- Rebuild heat exchangers, tube sheets, and other water-circulating equipment

- Use as a top coat for exceptionally smooth repaired surfaces

Armor Plate – Steel – Fast (K-081)

Armor Plate – Steel – Fast is a two-component, steel-filled epoxy designed for repairing worn shafts, sheaves, and castings or for use in tool- and die-making applications. It offers excellent corrosion resistance and resistance against a wide range of chemicals. It’s also resistant to shrinkage, expansion, and distortion. Armor Plate – Steel kits are supplied with resin and hardener pre-measured in the correct ratio, which makes for easy measuring and mixing on-site.

Common uses for Armor Plate – Steel – Fast include:

- Repairing cracks or holes in engine and pump casings, pipes, tanks, and other equipment

- Resurfacing pitted or damaged metal surfaces

- Repairing shafts and hydraulic rams

- Use as a structural adhesive for metal bonding

Products for Mine Maintenance and Beyond from Copps Industries

At Copps Industries, we offer best-in-class epoxy systems tailored for the rigorous demands of the mining industry and beyond. With standout properties and benefits, our solutions are designed to extend the life of your most critical equipment, minimize downtime, and maximize throughput.

Whether you need to deep grout large machine bases, protect equipment from erosion and corrosion, or perform quick, effective repairs, our line of epoxy products has you covered. Our solutions are engineered to help your equipment reach its full lifespan and deliver optimal performance in the harshest environments. For more information about our industrial strength solutions for heavy-duty applications, contact us and request a quote.

Request Quote

Request Quote