Electronic assemblies need to be protected from factors like vibration, shock, thermal dissipation, moisture, and corrosive agents. This protection can be achieved through a process called potting. Potting involves the process of filling an electronic assembly with a compound that provides permanent added protection to the assembly.

Electronic assemblies need to be protected from factors like vibration, shock, thermal dissipation, moisture, and corrosive agents. This protection can be achieved through a process called potting. Potting involves the process of filling an electronic assembly with a compound that provides permanent added protection to the assembly.

There are several potting compounds to choose from, each featuring different viscosities, cure condition requirements, and other characteristics. Urethane, silicone, and epoxy are all widely used compounds. In this blog post, we will discuss everything you need to know about epoxy potting compounds.

What are Epoxy Potting Compounds?

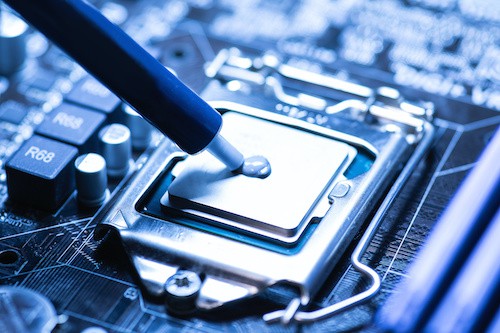

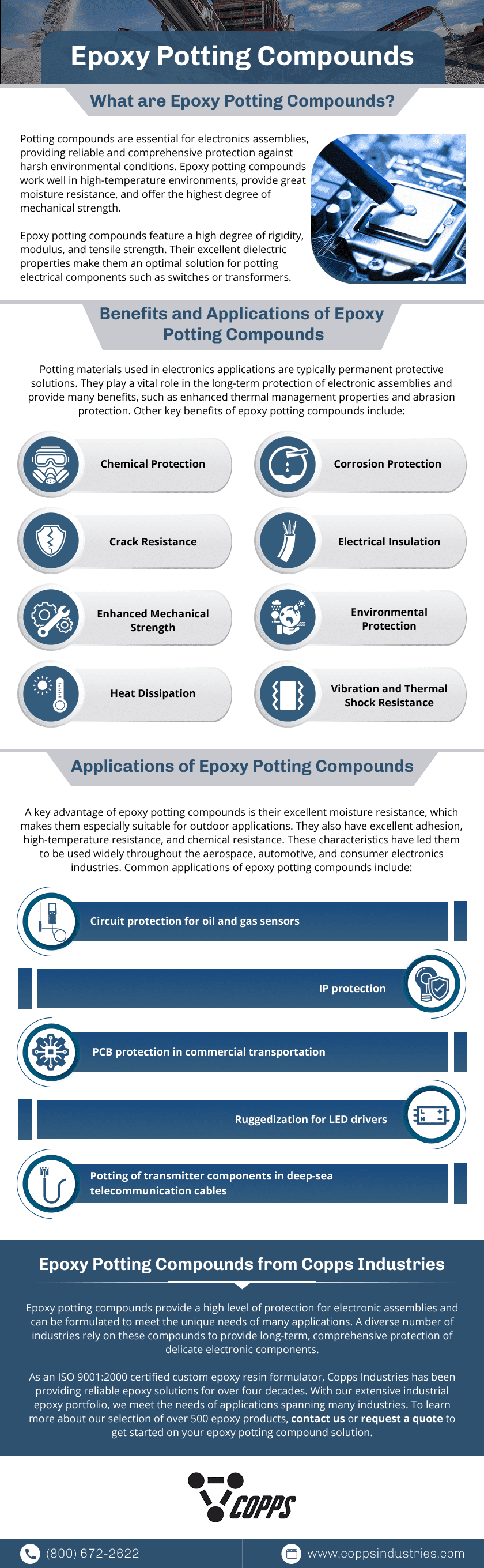

Potting compounds are essential for electronics assemblies, providing reliable and comprehensive protection against harsh environmental conditions. Epoxy potting compounds work well in high-temperature environments, provide great moisture resistance, and offer the highest degree of mechanical strength.

Epoxy potting compounds feature a high degree of rigidity, modulus, and tensile strength. Their excellent dielectric properties make them an optimal solution for potting electrical components such as switches or transformers.

Benefits and Applications of Epoxy Potting Compounds

Potting materials used in electronics applications are typically permanent protective solutions. They play a vital role in the long-term protection of electronic assemblies and provide many benefits, such as enhanced thermal management properties and abrasion protection. Other key benefits of epoxy potting compounds include:

- Chemical protection

- Corrosion protection

- Crack resistance

- Electrical insulation

- Enhanced mechanical strength

- Environmental protection

- Heat dissipation

- Vibration and thermal shock resistance

A key advantage of epoxy potting compounds is their excellent moisture resistance, which makes them especially suitable for outdoor applications. They also have excellent adhesion, high-temperature resistance, and chemical resistance. These characteristics have led them to be used widely throughout the aerospace, automotive, and consumer electronics industries. Common applications of epoxy potting compounds include:

- Circuit protection for oil and gas sensors

- IP protection

- PCB protection in commercial transportation

- Ruggedization for LED drivers

- Potting of transmitter components in deep-sea telecommunication cables

The low viscosity, self-leveling characteristics of many grades of epoxy compounds make them ideally suited for high-volume production applications and protecting fragile components. Several grades of epoxy potting compounds can be formulated to meet the specific requirements of different applications. These compound types range from very low to higher viscosities and feature different working times and other characteristics. For example, epoxy resins can be formulated to be thermally conductive, flame retardant, and curable at room temperature or high temperatures.

Epoxy Potting Compounds from Copps Industries

Epoxy potting compounds provide a high level of protection for electronic assemblies and can be formulated to meet the unique needs of many applications. A diverse number of industries rely on these compounds to provide long-term, comprehensive protection of delicate electronic components.

As an ISO 9001:2000 certified custom epoxy resin formulator, Copps Industries has been providing reliable epoxy solutions for over four decades. With our extensive industrial epoxy portfolio, we meet the needs of applications spanning many industries. To learn more about our selection of over 500 epoxy products, contact us or request a quote to get started on your epoxy potting compound solution.

Request Quote

Request Quote