Category Archive: Polyurea vs Polyurethane

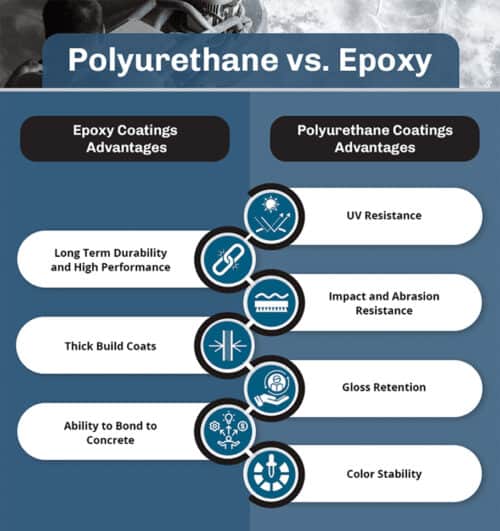

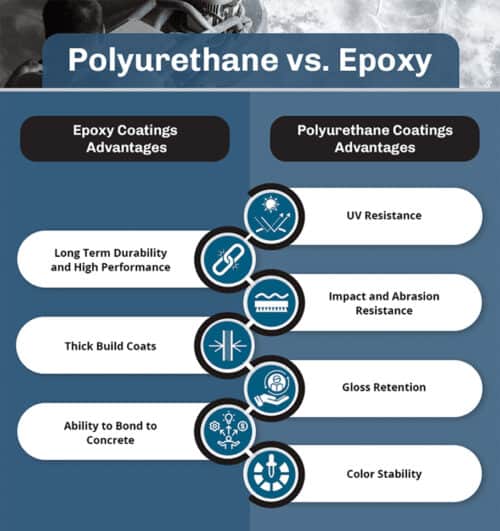

Whether you’re undertaking a DIY craft or home improvement project or overseeing a large commercial project, it’s important to understand the nuances between polyurethane and epoxy coatings. These two coatings may seem similar, but each has distinct properties and advantages tailored to specific needs.

There are many uses for epoxy and polyurethane coatings, and selecting the right coating is important for long-lasting protection and performance.

For example, consider a homeowner who is renovating their garage floor. They require a coating that can withstand frequent traffic, spills, and potential oil leaks. On the other hand, an industrial facility manager may be tasked with safeguarding concrete surfaces against corrosion, impact, and harsh chemicals.

In each scenario, the choice between polyurethane and epoxy coatings hinges on factors such as substrate type, project requirements, and environmental conditions. Learning the unique properties and advantages of each coating will help you choose the right solution for your project.

Let’s take a look at these popular coatings, starting with a clear definition of epoxy and polyurethane.

What is Epoxy?

Epoxy is a hard-wearing resin system known for its surface tolerance and adhesion to various substrates. It offers versatility with properties like chemical resistance or fast-setting. Depending on the intended application, you may choose any one of several epoxy options.

Here are some key advantages of epoxy coatings:

- Surface Tolerance: Epoxy coatings excel in adhering to different surfaces, making them ideal for a wide range of applications.

- Ability to Bond to Concrete: Epoxies can chemically and mechanically bond with concrete, making them a preferred choice for coating concrete substrates.

- Durability and Impact Resistance: Once treated with an epoxy resin, surfaces have a harder, more durable surface with impressive impact resistance.

- Thick Build Coats: Thanks to their thickness, epoxy coatings are able to self-level and create smooth surfaces by filling cracks and blemishes.

What is Polyurethane?

Polyurethane is a versatile polymer compound that is commonly used in various applications. It offers a softer alternative to epoxy with remarkable scratch resistance and flexibility, making it ideal for flexible substrates.

Here are some key advantages of polyurethane coatings:

- UV Resistance: Polyurethane coatings are highly resistant to UV radiation, making them suitable for outdoor applications.

- Impact and Abrasion Resistance: They offer excellent protection against impacts and abrasions, maintaining the integrity of the coated surface.

- Gloss Retention: Polyurethane coatings retain their glossy finish over time, enhancing the aesthetic of the coated surface.

- Color Stability: They also provide long-term color stability, ensuring the coated surface maintains its appearance.

Applications and Uses

Both epoxy and polyurethane coatings find applications in various industries and projects. Epoxy offers higher levels of rigidity and adhesion, making it suitable for harder surfaces, like concrete and areas with high physical impacts. Polyurethane, on the other hand, is often chosen for its cosmetic performance characteristics that offer holistic protection for the entire system.

Choosing the Right Coating

When selecting between epoxy and polyurethane for your project, consider the following factors:

- Surface Type: Determine the type of surface you’re coating. Epoxy is ideal for harder surfaces, while polyurethane is better suited for flexible surfaces.

- Project Requirements: Consider the specific needs of your project, such as durability, UV resistance, or aesthetic appeal.

- Cost Consideration: Polyurethane coatings may cost more upfront, but they can offer long-term savings in certain applications.

- Environmental Conditions: Think about the environmental factors your project will face, such as exposure to high traffic or harsh chemicals.

Understanding the unique properties and advantages of epoxy and polyurethane coatings will help you select the right solution for your next project. Whether you prioritize durability, flexibility, or aesthetic appeal, there’s a coating option that suits your needs.

Industrial Epoxy Solutions from Copps Industries

For applications that require significant durability and high performance, epoxy resins are the ideal choice. Since 1979, Copps Industries has been dedicated to providing the finest industrial epoxies in the field. Over decades of experience, we’ve successfully diversified our lineup to offer more than 500 products in 27 countries. Markets we serve include:

- Electronics

- Civil Engineering

- Structural Adhesives

- Aggregate/Mining

We’re dedicated to manufacturing products of the highest caliber at our ISO 9001:2015-certified facilities. Contact us or request a quote today and learn more about our epoxy resin solutions.

In the dynamic, demanding world of aggregate and mining, there’s zero time for unplanned equipment downtime. When it hits, production halts. Profitability crashes. And jobs can be at stake.

To help minimize the ripple effects of downtime, on-site managers and engineers alike count on crusher backing solutions from Copps. For over 45 years we’ve established a proven track record – as well as a trust – that once our solutions disappear into critical parts of a machine, they do what we promise: help keep operations online, on time, and equipment operating efficiently for longer. For anything that needs crushing, under the most extreme conditions, anywhere in the world. And it’s with the world in mind that we develop our products. Not just for the job at hand today, but with long-term implications in mind for your people and the environment as well. In fact, Copps is the only company to date to offer non-corrosive versions of standard and high-performance crusher backing options. We don’t just lead this market in environmentally conscious solutions – we are the market.

Raising the Bar for Your Toughest Jobs

While some well-known, established companies choose only to offer one type of backing product, our experience, expertise, and chemistry tell us that different materials and machines require different solutions.

That’s why we formulate and offer both standard as well as premier, high-performance versions of our products, designed specifically for your toughest jobs. All as we continue to lead the way in our commitment to the environment by offering eco-conscious versions of our crusher backing solutions.

Recommended for use in most (including severe) crushing applications. With uniform consistency, pourability, and cured toughness it offers elevated compressive strength, service temperature, and impact resistance. Does not contain VOCs, butyl glycidyl ether (BGE), or nonylphenol.

A DOT non-corrosive version of our standard backing formulated to address environmental, workplace safety, and shipping concerns. It provides the same support or “backup” for manganese steel or alloy wear parts in cone and gyratory crushers as our traditional material, and is butyl glycidyl ether (BGE), VOC, and nonyl phenol free!

The ultimate backing material for the toughest, most demanding crushing applications. Uniquely designed with extreme impact resistance, very low water absorption, and the ability to withstand hard or abrasive material and high-temperature crushing environments. Does not contain VOCs, butyl glycidyl ether (BGE), or nonylphenol.

The DOT non-corrosive version of our current ultimate backing material. Designed to engage the most challenging crushing conditions: gyrators, primary crushing, wet crushing, and hard or excessively abrasive media. Does not contain BGE, VOCs, or nonylphenol. It offers exceptional heat, water, and shrinkage resistance.

What Crusher Backing Compounds Do For You

The stresses your equipment faces day in and day out, hour after hour, are immense. Our crusher backing compounds help protect it all from unnecessary damage and assist in long-term wear by filling the open cavities behind wear parts and supporting crushing wear surfaces. In doing so, our compounds help to minimize the effect of friction, vibration, and impact on the machinery during crushing operations. They offer a range of benefits for mining and aggregate operations including:

Extended Machinery Life

Applying crusher backing compounds on an appropriate maintenance schedule substantially extends the life of equipment and related components, minimizes downtime, and lowers replacement part costs.

Low Shrinkage

Using a properly formulated crusher backing compound engineered to manage shrinkage during the hardening or curing stage greatly reduces the risk of voids and misalignments between liners.

High Strength

Our compounds offer a higher level of compressive strength, a broader array of service temperatures, and higher impact and vibration resistance to improve component and machine efficiency and durability.

Gap Elimination

Eliminating wear liner gaps and smoothing alignment errors provides equipment with superior impact resistance compared to equipment not treated with a crusher backing compound.

Performance, Profitability, and More.

Across the US and around the world, mining companies today are coming under scrutiny. While keeping up performance and remaining profitable will always be job number one, mining leaders are being asked to do more than ever. Like enhancing commitments to the environment and making conscious efforts to improve workforce health and safety.

With the crusher backing solutions offered by Copps on-site and at the ready, you can do both.

To learn more about our crusher backing compounds or other epoxy-based solutions, contact us or request a quote.

Put the power and innovation of Copps Industries to work for you today. From our commitment to the environment and sustainability to our private label offerings and “virtual chemist” opportunities, we’re ready to help create better solutions for you.

Polyurea and polyurethane are ideal for manufacturing protective linings and coatings. The two materials share many similarities and can often be used interchangeably. However, there are several distinct differences that should be considered when choosing between the polymer compounds. From chemical composition to curing time, these differences lend unique advantages and disadvantages depending on the intended application.

Polyurea vs Polyurethane

Polyurethane and polyurea share many similarities — one of the biggest being that, in their final forms, they are capable of curing into very flexible to very stiff coatings. Polyurethane has been a standard sealant and adhesive material for decades. It is created from a reaction between a polyol and an isocyanate, creating a waterproof coating with high resistance to certain acids. This makes polyurethane ideal for use in the food industry, where frequent contact with food-related acids is expected.

Polyurethane and polyurea share many similarities — one of the biggest being that, in their final forms, they are capable of curing into very flexible to very stiff coatings. Polyurethane has been a standard sealant and adhesive material for decades. It is created from a reaction between a polyol and an isocyanate, creating a waterproof coating with high resistance to certain acids. This makes polyurethane ideal for use in the food industry, where frequent contact with food-related acids is expected.

Polyureas are a more modern addition to the sealant and coating industry. They are formed when multifunctional amine reacts with an isocyanate. The compound reacts faster than polyurethane, creating a gel in only seconds after mixing the ingredients.

Advantages and Disadvantages of Polyurea vs Polyurethane

The unique compositions of the two substances provide them with advantages and disadvantages based on the application. Both compounds are ideal protective coatings for concrete, reducing the damaging effects of chemical exposure, corrosion, abrasion, and moisture. Polyurethanes offer the following advantages:

- Facilitates application in two parts for more versatility

- Less expensive than polyurea

- Resistant to damaging UV rays

- Curing time can be set from one minute to several hours depending on the mixture

Polyurethanes also have unique disadvantages compared to polyurea coatings. When applying polyurethane, users must pay attention to the temperature and humidity level. The chemical reaction is sensitive to temperatures less than 32°F. Polyurethane coatings may blister when applied at humidity levels higher than 70%.

Polyurea offers the following advantages:

- Pleasant appearance with various pigment options

- Easy to work with

- Applicable at temperatures as low as -20°F

- Performs well in humid environments

- Quick curing time allows for application in harsh conditions

- Withstands extreme environments

Several factors put polyurea at a disadvantage compared to polyurethane. Polyurea can be expensive to apply because technicians must be highly trained to work with the incredibly fast-curing compound before it sets. With little resistance to UV damage, the appearance of polyurea can become chalky, discolored, and dull when exposed to UV rays.

Applications of Polyurea vs Polyurethane

Polyurea and polyurethane’s unique characteristics make them ideal for use in differing applications. Polyurea’s resistance to harsh environments makes it ideal for construction applications. It is suitable for bridges, car parks, decks, roof repairs, and aesthetically appealing surface coatings for floors. The oil, coatings, marine, and other industrial industries depend on polyurea for a wide range of uses.

Polyurethane’s low cost and manageable application make it suitable for cars, furniture, housing, and shoes. It can also be used in manufacturing hard protective coatings and foam insulation for mattresses.

Polyurea vs. Polyurethane Coatings From Copps Industries

Polyurea and polyurethane are valuable coating and lining compounds for many industries. While polyurethane coatings are affordable and offer UV resistance, they are more susceptible to damage in humid or freezing environments. Polyurea resists extreme conditions and cures incredibly fast but can be more expensive.

Copps Industries has over 40 years of experience in the epoxy business and maintains an ISO 9001-2015 certification to deliver the highest quality products and services. We focus on providing industry-leading customer service and high-quality products. We offer a wide range of products to suit numerous applications. At Copps Industries, we formulate each of our systems in the USA. We are building the future of green epoxies by developing environmentally friendly solutions.

Contact us to speak with our experts about our capabilities and custom solutions for your application or request a quote today.

Polyurethane and polyurea share many similarities — one of the biggest being that, in their final forms, they are capable of curing into very flexible to very stiff coatings. Polyurethane has been a standard sealant and adhesive material for decades. It is created from a reaction between a polyol and an isocyanate, creating a waterproof coating with high resistance to certain acids. This makes polyurethane ideal for use in the food industry, where frequent contact with food-related acids is expected.

Polyurethane and polyurea share many similarities — one of the biggest being that, in their final forms, they are capable of curing into very flexible to very stiff coatings. Polyurethane has been a standard sealant and adhesive material for decades. It is created from a reaction between a polyol and an isocyanate, creating a waterproof coating with high resistance to certain acids. This makes polyurethane ideal for use in the food industry, where frequent contact with food-related acids is expected.