Category Archive: Epoxy Resins

When it comes to composite manufacturing, you can choose from many materials and methods, each with unique advantages. Among the choices, two techniques stand out: the dry process and pre-impregnated (or pre-preg) process. Understanding the differences between the two will help you settle on the most effective way to bring your project to life.

Here, we’re comparing the dry process versus pre-preg to shed light on their characteristics and applications. From cost efficiency to customization to performance, you’ll learn that the dry process is often the best composite epoxy solution.

What’s the difference? Dry Process vs. Pre-preg Solutions.

Dry process and pre-preg solutions are two common methods for applying epoxy resin to fabric substrates. Each method comes with its own characteristics and applications.

Dry Process

In the dry process, a raw carbon fiber tow or fabric is loaded into a mold and epoxy resin is used to saturate the substrate. The resin then cures, bonding the fibers together to create a solid composite structure.

Characteristics

- Requires separate handling and application of resin and dry fibers

- Offers flexibility and customization in material selection and layup techniques

- Can reduce material waste and enhance performance

- More cost-effective and compatible with automation compared to pre-preg solutions

Pre-preg Solutions

Pre-preg refers to a composite material where reinforcing fibers are pre-impregnated with a resin before use. This pre-impregnation is typically done by the manufacturer, who applies a precise amount of resin onto the fibers and then cures them to a partially cured state. The pre-preg materials are then stored in a freezer until they are ready to be used. When heated, the resin cures, bonding the fibers together to create a solid composite structure.

- Characteristics:

- Reinforcing fibers are already impregnated with resin, simplifying handling and processing

- Requires freezer storage to prevent premature curing

- Offers consistency in material properties and performance

- Typically more expensive than the dry process due to additional processing and handling

Both dry process and pre-preg solutions have their advantages, and the choice between them depends on cost, production volume, and performance specifications. The dry process offers several benefits that make it the best choice for most applications:

The dry process involves lower material costs compared to pre-preg solutions. Pre-preg materials are often more expensive due to additional processing and handling.

The dry process allows for easier and faster customization and flexibility in material and techniques. You can tailor the resin type, fiber orientation, and layering technique to meet specific requirements and optimize the finished product.

With pre-preg solutions, unused or excess material can lead to waste due to limited shelf life, resin wasted in pattern cuts, and storage requirements. In dry processing, the fibers and resin are combined in the mold as needed, which reduces waste and limits your environmental impact.

- Improved Handling and Storage:

Dry materials are easier to handle and store than pre-preg solutions, which require storage in freezers. This simplifies logistics and reduces the risk of material degradation during transportation or storage.

Pre-preg solutions require additional processing steps and curing time, while dry processing offers faster cycle times and increased efficiency. The dry process allows you to streamline production without compromising quality.

Copps Industries Composite Epoxy Solutions

If you want to streamline your production processes, enhance product performance, and reduce costs, consider dry processing as the ideal composite epoxy solution. From cost-effectiveness and customization to enhanced performance, it offers benefits across a range of applications.

Copps Industries offers a range of standard and custom epoxy resin systems designed to meet your needs. Whether you need assistance with formulation selection or a solution tailored specifically to your project, we’re here to help. Contact us to place your order or request a quote.

When it comes to your business, the right partners can mean the difference between stagnation and success. But when faced with making a choice, distinguishing between a transactional supplier relationship and a transformational partnership can be a challenge.

At Copps Industries, we understand the pivotal role of partnership in delivering long-term value. With a mindset of mutual success, we strive to redefine manufacturer-supplier collaboration. We believe that beyond providing high-quality products, the right partner should offer transparency, fill knowledge gaps with their expertise, and provide proactive support.

We’re breaking down five critical questions to ask when you’re evaluating potential supplier partnerships.

1. How do you approach product development?

When assessing a potential partner, it’s important to understand their approach to product development. Are they focused on pushing the products already in their portfolio, or are they willing to tailor solutions to your specific needs and requirements?

At Copps Industries, we pride ourselves on a solutions-oriented approach, working closely with our customers to develop customized solutions that deliver real value. Plus, we continually push for improvement and innovation by refining existing formulations and venturing into uncharted territories.

2. What level of involvement can we expect from your technical experts?

Access to technical expertise can be a game-changer when it comes to coping with complex challenges. Does your prospective partner have experts on staff who can fill knowledge gaps and provide insights? Are they available to you?

Copps Industries offers easy access to a diverse team of technical experts dedicated to empowering your success. And with the Virtual Copps’ Chemist, you get to harness our expertise in every aspect of product development, use, and delivery.

3. How do you handle situations where a solution is not immediately apparent?

In the face of uncertainty or ambiguity, a supplier should be able to adapt. Does your potential partner demonstrate a willingness to experiment, test hypotheses, and collaborate to find the right solution?

Copps Industries collaborates with customers, leveraging our collective expertise and resources to overcome any obstacle that appears in our path. We’re not deterred by a challenge; we thrive on working relentlessly for a solution.

4. How do you ensure the formulas provided meet our expectations?

Trust is the cornerstone of any good partnership. Does it appear you can rely on your partner to deliver formulas that meet your needs in terms of quality and performance? Or are they simply serving up the cheapest solution?

We set the standard for quality, working alongside our customers to pave the way for performance and reliability. You can depend on Copps Industries to deliver products that exceed your expectations.

5. What measures do you take to maintain confidentiality and protect our brand?

In today’s competitive landscape, confidentiality is non-negotiable when you’re seeking a private label supplier. Your partner should be committed to safeguarding your brand and protecting your reputation.

At Copps Industries, we supply both private label as well as direct to the industry. No matter how we partner with you, our mindset of mutual success means we become an extension of your team. We work with respect and discretion, taking every measure to work with integrity and maintain the confidentiality of your custom solutions.

Assessing Supplier Responses

As you evaluate potential partners, pay close attention to their responses to these questions. Here are three red flags to watch out for when assessing supplier responses:

- Lack of Transparency: If a supplier is vague in their responses, it may indicate a lack of transparency or a reluctance to engage in open communication. Beware of partners who won’t speak openly about their capabilities and processes or how they work through potential challenges.

- Limited Technical Expertise: A supplier who offers limited access to technical experts or is unwilling to share their expertise may not be equipped to provide the level of support you need. Make sure your partner is committed to providing help at every turn.

- Inflexibility: Partners who resist experimentation, testing, or exploring new solutions may hinder your ability to adapt and innovate. Look for signs of flexibility, openness to new ideas, and a willingness to collaborate on solutions that drive mutual success.

When you watch for these red flags, you can better assess the fit of potential suppliers and identify the right partner who will be invested in your success. Choose a supplier who listens to your needs, freely shares expertise, and demonstrates collaboration. Steer clear of those who signal they’ll operate on their own agenda.

Partnership is Paramount at Copps Industries

Selecting a supplier can be challenging. But with the right approach, choosing a partner can become a catalyst for growth and innovation. Prioritize partnerships built on trust, expertise, and shared success. As you make your assessment, remember that Copps Industries is dedicated to your success at every stage of your journey. Contact us today to learn more about Copps Industries and get started collaborating on a custom solution.

In a world where innovation drives progress, industries from automotive to marine to aerospace are constantly seeking ways to elevate their performance. At Copps Industries, we’re focused on understanding the evolving needs of our customers and developing advanced composite epoxy solutions that empower them to stay ahead of the curve in their fields.

Here, we’re exploring trends in each industry and real-world applications that influence the most important features industry leaders look for in composites across land, sea, and air.

Land: The Automotive Industry

In the automotive sector, performance and sustainability are paramount. Copps Industries’ composite epoxy solutions help drive advancements in both motorsports and OEM applications.

- Advanced performance: Especially in high-performance motorsports, there’s a high demand for lightweight solutions that enhance performance. Our composite epoxies offer unparalleled durability and NVH (noise, vibration, and harshness) performance. By replacing metallic components with lightweight composites, manufacturers can achieve significant weight savings without sacrificing performance.

- Increased production capability: OEMs that produce hundreds of thousands of parts per year per vehicle line are looking for new processing techniques to increase their capabilities. We meet this need with rapid-cure epoxy resins that enable faster production rates without compromising on quality.

Beyond leveraging rapid cure materials, manufacturers are also improving their processing times through automation. In many cases, our partnership with customers extends beyond supplying materials to include consult on process optimization that can help them enhance their capabilities and meet their production goals.

- Recyclability: Environmental impact is a growing concern across industries, including the automotive sector. In automotive applications, the average life of materials is around 12 years. We actively work towards sustainable solutions, collaborating with stakeholders to repurpose materials and streamline their integration into parts for next-generation vehicles. By recycling and repurposing materials, manufacturers are shaping a more sustainable future.

Sea: The Marine Industry

In the marine sector, quality, performance, and cost-effectiveness top the list of the industry’s demands. Copps Industries delivers on all fronts with advanced composite epoxy solutions.

- Quality and performance: One significant shift in the marine industry is the move from polyester to vinyl ester resins, which have an epoxy base. These resins offer superior mechanical performance and reduced shrinkage, making them ideal for marine applications. Our epoxy solutions align with this trend, providing unmatched performance without losing quality.

- Faster, more repeatable processes: The transition from open mold to closed mold processing is revolutionizing marine manufacturing. Our rapid cure systems streamline production, reducing post-processing time and increasing efficiency. And with fewer defects and less scrap, manufacturers can achieve higher yields and lower production costs.

- Sustainability: As stricter regulations emerge around the use of VOC products, our epoxy solutions have become a preferred choice in the marine sector. And in an era of rising raw material prices, the switch to epoxy can provide improved performance with less of an increase in cost. Through compliance and enhanced performance, we help customers maintain competitiveness in the market.

Air: The Aerospace Industry

In the aerospace sector, the focus is on lightweight solutions, performance, and durability. Copps Industries helps customers in this sector through formulations that meet the strict requirements of aerospace applications.

- Lightweight solutions: Aerospace demands materials that offer significant weight savings without compromising performance. Even a marginal weight reduction translates into significant cost savings. In fact, saving just one pound in weight might equate to $20,000 in savings over the lifespan of an aircraft. The industry’s relentless pursuit of lightweight solutions is driving the adoption of innovative materials, which we continually help them explore.

- New methods of processing: The aerospace industry is in constant pursuit of improvement in both materials and processes. From crafting advanced resin formulations to exploring new filament winding methods, we’re helping customers achieve quicker production and shorter lead times. Our collaboration with industry leaders in aerospace underscores our commitment to partnering with customers to advance not only their materials but also their processes.

- Durability and strength: Durability and strength are critical considerations in aerospace applications. Our composite epoxy solutions meet the rigorous demands of aerospace environments, and by continuously advancing our resin formulations, we help customers achieve new levels of performance and reliability.

Copps Industries: Driving Innovation Across Sectors

Copps Industries is proud to drive innovation across the automotive, marine, and aerospace sectors with our lineup of composite epoxy solutions. By continuously pushing the boundaries of product development, we empower manufacturers to achieve new levels of quality and performance. Whether you’re looking for advanced performance in automotive applications, sustainable solutions for marine manufacturing, or lightweight materials for aerospace advancements, Copps Industries can help. Contact us to discuss your specific needs, explore potential solutions, or request a quote. Together, we can conquer innovation by land, sea, and air.

Stronger yet lighter weight. More flexible yet more durable. Thermally insulated. Versatile. And chemical or corrosion-resistant on top of it all. If the part or component you need must be some, all, or even more of these, your best solution is an epoxy composite.

If you need it fast and done to your exacting standards, the only solution is to partner with Copps.

Here, collaboration with our customers is king. Short lead times and fast turnarounds are to be expected. And access to our entire team, from service to formulation, to support after you have what you need – is guaranteed.

And because we service a wide range of markets outside of the epoxy composites world, we’re able to connect you with different expert perspectives and new ideas. The kind other sources simply can’t provide.

Reinforcements: Putting it All Together

Your job, your product, your needs are unique. What’s not unique is the fact that epoxy resin alone typically doesn’t provide enough structural integrity to meet the reliability and durability you need.

We cater our epoxy development to create a low-density material with a high strength-to-weight ratio to meet the needs of diverse applications specifically with each of these types of reinforcements:

- Carbon fiber

- Fiberglass

- Aramid

- Natural fibers: jute, flax, and kenaf

- Exotic fibers: boron, basalt

- Particulate fillers: ceramic, silica, metal

Properties and Advantages of Different Reinforcements

Each reinforcement material offers its own unique characteristics and benefits. The best material for your specific application depends on its intended use. Some of the most common properties reinforcements offer include:

- Impact resistance

- Stiffness

- High strength-to-weight ratio

Not Just a Manufacturing Process. Your Process.

For every type of process, there’s a set of variables that come into play – as well as the desired outcome. That’s why we develop products not just for the process type, but for the individual customer variation within each process type. That’s what makes Copps unique.

Through customer collaboration, meticulous attention to detail and precision, we develop products for all of these processes:

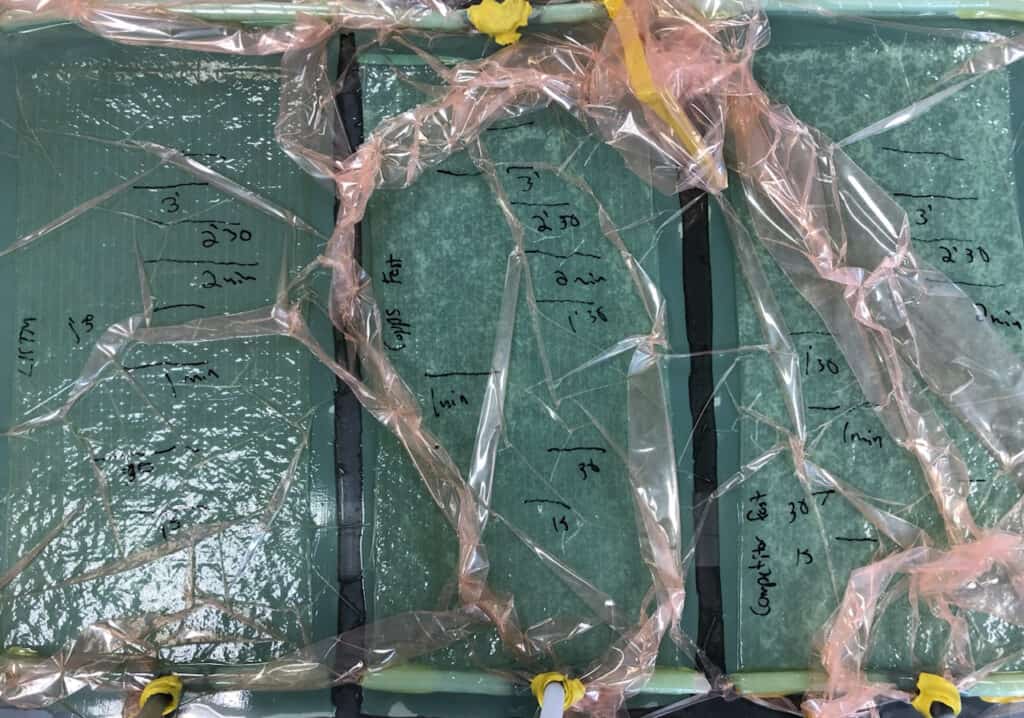

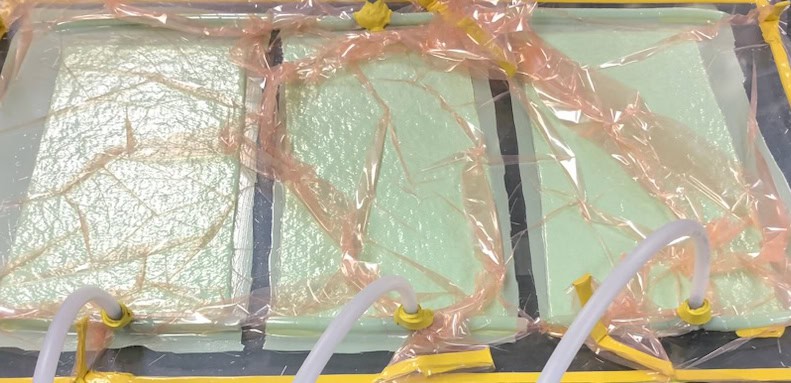

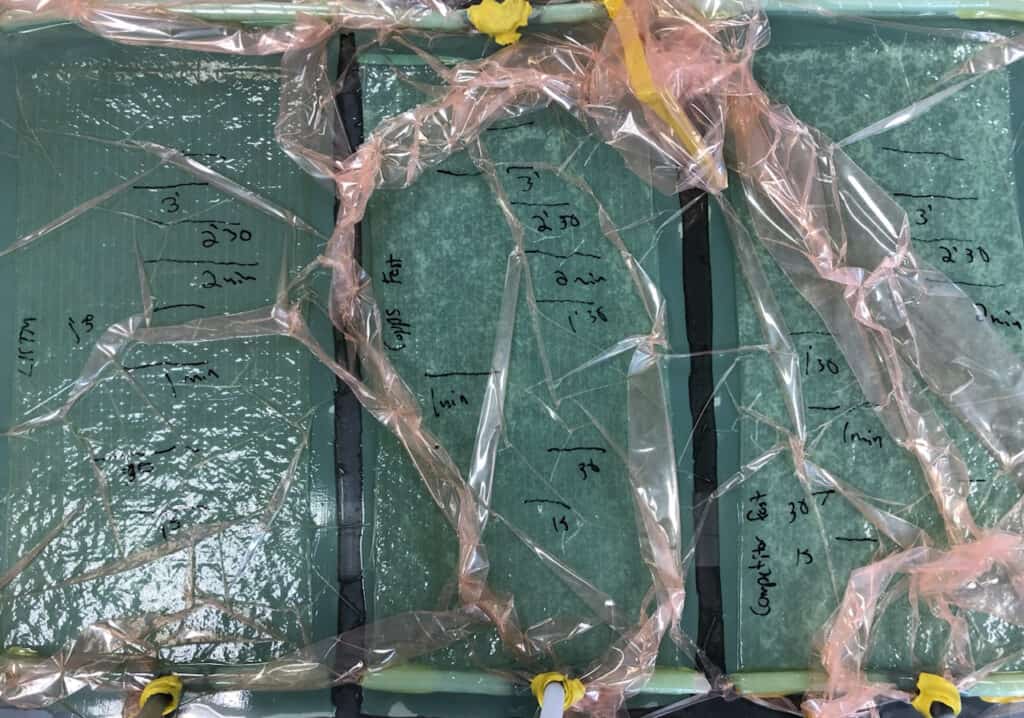

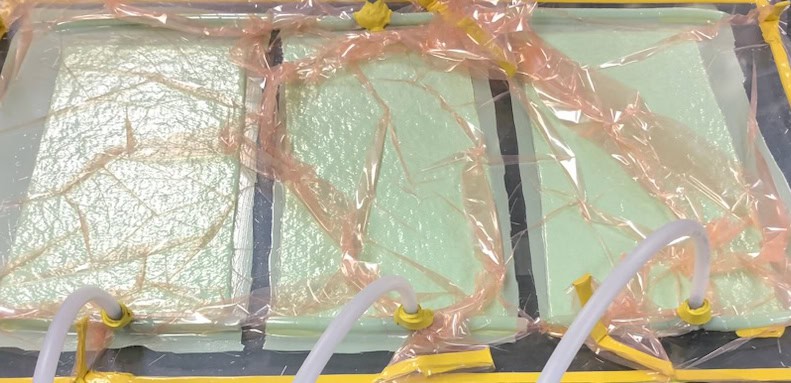

- Vacuum Bagging: An open molding technique (including Wet Bagging) that places mechanical pressure on a laminate during its cure cycle. Designed to achieve higher-than-normal properties of Hand Layup without the technical challenges of VIP.

- Hand Layup: The simplest composite molding method available where fiber reinforcements are wet out by hand and manually positioned into a mold.

- High-Pressure Resin Transfer Molding (HPRTM): Rapidly becoming popular in the automotive, industrial, and agricultural industries, this is a high-output process where dry reinforcement fabrics are placed into metal tooling inside of a high-tonnage hydraulic press. Resin is then injected under very high pressures for precise part geometry and repeatability. It can also be automated in a 5-step process.

- Light Resin Transfer Molding (LRTM): A closed-mold process similar to resin transfer molding where both the A and B molds are made of composites. This technology is frequently applied in production of boats and water equipment but has infinite possibilities beyond, including car body elements, trailers, aircraft, and more.

- Vacuum Assisted Resin Transfer Molding Process (VTRM): Another variation of RTM, this too is a closed-mold manufacturing process. Unlike LRTM, the top portion of a mold tool is replaced with a flexible vacuum bag, and vacuum only, no injection, is used to assist in resin flow. Currently most used in composite production where only one part of the laminate is visible.

- Vacuum Infusion Process (VIP): A low production-level, closed-mold process with a single-sided tool that is loaded with dry fabrics. A flexible film is then used to apply full vacuum to the part and the resin is drawn into the reinforcement through the vacuum applied. Popular infusion resin types include epoxy, polyester, and vinyl ester.

- Filament Winding: The process of winding resin-impregnated strands of fiber around a rotating mandrel to create a composite structure. Creates high-fiber loading with good directional strength for extremely strong composite products.

- Pultrusion: A high throughput process for making straight solid shapes where dry fibers are dipped in resin and pulled through a heated metal die creating the part profile and curing in one step. Best suited for high-volume, single-direction reinforced products like rods, poles, trim, flat panels, and more.

Regardless of the method to suit your process, our quality control and testing are vital to ensure the final product will meet the required standards.

Markets Served by Our Epoxy Composites

Where in the real world will you find epoxy composite solutions from Copps?

Virtually anywhere. By land, sea, and air (even above and beyond) Epoxy composites are used throughout nearly every industry.

In the automotive sector, they help create vehicle parts for increased performance and weight reduction. Composites can be used to form structural components in the construction industry. The marine industry relies on them to manufacture boat hulls, decks, consoles, and hatches. In aerospace, they’re a popular choice for aircraft components thanks to their lightweight nature and strength. Here are just some of the markets we’re currently serving:

- Aerospace

- Marine

- Construction

- DoD

- Industrial

- Motorsport

- Automotive

- Sports & Leisure

Exceeding Your Epoxy Composite Expectations

If you have an epoxy composite need or challenge, call on Copps Industries. We’ll create a solution you can have confidence in. Performance and reliability can’t be topped by the day-in and day-out experience you’ll have working with our team of experts. When you’re ready to get started on your next, best composite, contact us today.

In an environment marked by constant change, many businesses grapple with ever-shifting market dynamics, technology, and rules and regulations. Keeping pace demands expertise beyond the reach of most—no one organization has all the knowledge and resources to navigate this terrain alone. That’s why it’s so important to seek out partners who complement your capabilities and are deeply invested in your success.

Enter Copps Industries’ Virtual Chemist, a concept that redefines manufacturer-supplier collaboration. Here, we’re exploring what the Virtual Chemist is and how this innovative resource can benefit you.

The Virtual Chemist Concept

The origin of the Virtual Copps’ Chemist lies in our commitment to customer success. From the start, we recognized that most manufacturers don’t have the technical expertise to specify their formulations. You might know what you want but not necessarily how to get there. That’s where our knowledgeable team steps in to lend their insights. Since 1979, we’ve been developing custom formulations that fit a wide range of customer needs.

To picture the Virtual Chemist in practice, imagine this scenario: a customer might approach us with an inquiry about how a specific formulation would endure the extreme conditions of the African desert. While we may not have experienced this particular climate, we are confident in the product’s resilience in scorching Arizona temperatures. So, we work from there and collaborate to arrive at a solution.

This is the essence of the Virtual Chemist. Rather than succumbing to uncertainty, we leverage the collective expertise between our team and our customers. Together, we explore and innovate, pooling our resources and knowledge to address the challenge at hand.

There are countless other scenarios where the Virtual Chemist demonstrates its value. From keeping up with the latest chemical regulations to analyzing shipping requirements, we advise on every aspect of product development, use, and delivery. We also believe that access to these insights shouldn’t require exorbitant fees; it should come bundled with your custom solutions. This approach underscores our attention to your needs and our pursuit to exceed your expectations.

Commitment to Customer Success

Why does the Virtual Chemist concept matter to your success? Because the role of a supplier should transcend simply providing goods. The right partner serves as an ally who offers insights, fills knowledge gaps, and provides proactive support.

Through the Virtual Chemist, Copps Industries:

- Acts as an extension of your team. Our mindset of mutual success means that we work side-by-side with your team. With easy access to our staff and resources, you gain a partner equipped to navigate chemical and technical challenges, shipping intricacies, and evolving rules and regulations.

- Bridges knowledge gaps. We bridge the knowledge gaps our customers and other partners may have by freely sharing our expertise. Through educational initiatives for your sales or tech team, like the Rock Crusher College available to our Aggregate & Mining customers and other knowledge-sharing, market-specific events, we ensure you’re empowered with information and insights.

- Provides proactive support. We offer proactive support by staying ahead of market trends and regulation changes. This approach can transform your supplier relationship into a collaborative partnership that ensures you remain competitive and compliant.

Partnering with Copps Industries allows you to unlock the power of the Virtual Chemist at no additional cost. It’s all about recognizing that your supplier relationship is more than just transactional; it’s a strategic aspect of your success.

Partnership is Paramount at Copps Industries

The Virtual Copps’ Chemist is more than just a service—it’s a testament to our commitment to customer success. As a catalyst for collaboration, the Virtual Chemist allows you to harness our expertise, secure top-quality products, and gain a partner dedicated to moving your business forward.

As you assess your supplier relationships, look beyond the surface and evaluate the full spectrum of support they provide. The right partner makes all the difference as you navigate an increasingly challenging landscape. To learn more about Copps Industries and get started collaborating on a custom solution contact us today.

In the ever-evolving landscape of industrial solutions, Copps Industries stands out for our dedication to innovation and customer-centricity. With a commitment to meeting unique customer needs, our team continually pushes the boundaries in product development.

Copps Industries’ portfolio of products includes a range of solutions tailored to diverse industrial needs. From grouts to wearing compounds, each product reflects our commitment to quality, safety, and innovation. Many of these products have been developed in direct response to specific customer demands, emphasizing our agility and responsiveness to market needs.

One example is Copps XP-3000, a non-corrosive version of our ultimate crusher backing material, XP-2000. Designed to tackle the most challenging crushing conditions—ranging from gyratories to wet crushing environments—XP-3000 is a testament to our pursuit of excellence. Unlike its predecessors, XP-3000 is free from harmful substances like BGE1, VOCs, or Nonyl Phenol, giving it a DOT non-corrosive classification.

The difference between DOT and non-DOT classification lies in transportation regulations and safety standards. Certain products must meet Department of Transportation regulations for the safe transport of hazardous materials. These regulations mandate specific packaging, labeling, and handling requirements. DOT non-corrosive products, like XP-3000, contain substances that don’t require compliance with DOT corrosive chemical regulations. This classification simplifies logistics, reduces shipping costs, and ensures safer handling throughout the supply chain, providing customers with added peace of mind and cost savings.

The development of XP-3000 emerged from our deep understanding of the broad spectrum of customer requirements. Conceived to address the urgent needs of clients facing unforeseen situations, its ability to be airfreighted provided a solution to pressing delivery demands. Our ability to anticipate and respond to unique customer needs is tied to our ethos of constant innovation and adaptability.

Beyond XP-3000, our family of DOT non-corrosive products include:

- Non-Corrosive QFG epoxy grout (K-020): A DOT non-corrosive version of our REDBAC Quick-Fill Grout specifically formulated to address environmental, workplace safety, and shipping concerns.

- Non-Corrosive Deep Pour 3CE epoxy grout (K-840): A DOT non-corrosive version of our standard Deep Pour 3CE Grout specifically designed for pours up to 8 feet.

- Non-Corrosive Armor Plate-Ceramic wearing compound (K-046): A DOT non-corrosive version of our standard Armor Plate-Ceramic specifically designed to resist abrasive wear and corrosion in high wear areas.

These products have been formulated and reformulated to ensure top performance and top quality. Their DOT non-corrosive classification simplifies logistics, reduces costs, and serves as an example of our proactive approach to problem-solving.

At Copps Industries, it’s not just about the product; it’s about the philosophy driving its creation. We continually explore avenues for improvement, whether it’s through refining existing formulations or venturing into uncharted territories.

Copps Industries is more than just a supplier of products; we stand at the forefront of innovation and product development. As industries evolve and needs emerge, we pledge to continue pushing boundaries and advancing industry standards. Get in touch today to learn more, or request a quote to get started on your order.

Clear epoxies are commonly used for applications ranging from bars and tabletops to jewelry and crafts, enhancing protection and adding a glossy finish. But despite their popularity, it can be tough to determine the best epoxy type for your project.

The two most common types of epoxies are tabletop epoxies and casting epoxies. While the two are similar, they each have unique properties and ideal uses. Understanding the differences will help you choose the right solution for your project.

Let’s take a look at these two popular epoxies, starting with their different characteristics and applications.

Tabletop Epoxy vs. Casting Epoxy

Two of the most popular Diamond Clear Epoxy are tabletop epoxy and casting epoxy. The two share similarities but are different to work with and meant for different applications.

Tabletop Epoxy

As the name implies, tabletop epoxy is best for pouring over flat surfaces like tabletops, bars, counters, or resin art. It is a self-leveling epoxy meant for thin pours, typically 1/4″ thick or less. Pour thickness may vary depending on the application, but using tabletop epoxy for embedding thick objects requires multiple applications and several hours.

With its recommended 1:1 mixture ratio, tabletop epoxy is user-friendly for beginners and professionals. The main advantages of tabletop epoxy over casting epoxy include its higher viscosity and a faster cure time of 12-24 hours.

Casting Epoxy

Also known as deep pour resin, casting epoxy is used for thick pours up to 2″. Casting epoxy is commonly used for river tables, embedding and encasing objects, jewelry, and more. It has a lower viscosity than tabletop epoxy and a slower cure rate of 24-36 hours.

The longer cure time of casting epoxy allows for a longer working time, but care must be taken to prevent dust and debris from settling into the resin. The typical mixture ratio for casting epoxies is 2:1, although some manufacturers offer variations with a 1:1 or 3:1 ratio.

Advantages of Diamond Clear Epoxy

- Blush Resistance: Diamond Clear Epoxy does not blush or sweat even in high humidity conditions.

- Yellowing Resistance: UV-absorbing additives prevent Diamond Clear Epoxy from yellowing, which significantly prolongs the life of the product.

- Stabilizers: Our Diamond Clear Epoxy formulations incorporate stabilizers to meet commercial-grade performance expectations.

- High-Gloss Transparency: The formula for Diamond Clear Epoxy cures with a high-gloss, transparent finish. This polished appearance can usually be achieved with three coats or less.

- Simplified Mix Ratios: Simple mix ratios make Diamond Clear Epoxy easy to measure and mix. This reduces the risk of errors that may affect the finished product.

- Tough Surface Protection: Formulated to tough industrial standards, Diamond Clear Epoxy creates indestructible surfaces for your project. It results in long-lasting, maintenance-free surface protection that resists scratching and distortion.

- Wood Adhesion: Ideal for porous materials, Diamond Clear Epoxy protects surfaces while accentuating wood’s natural features.

- DOT Non-Hazardous Formulations: Diamond Clear Epoxy complies with DOT non-hazardous formulations for safety and ease of shipping.

Remember, no matter which epoxy you choose for your project, it’s important to read and follow the manufacturer’s instructions. Mistakes can make a big impact on the aesthetics and performance of your finished product.

Diamond Clear Epoxy from Copps Industries

Copps Industries’ Diamond Clear Epoxy line of products was specially formulated with our customers’ unique range of projects in mind. These epoxies can help you create beautiful, clear finishes quickly and easily, whether you’re sealing a bar top, creating a river table, or adding gloss to crafts or jewelry.

Our top two varieties of clear epoxy are Diamond Clear Epoxy Coat Tabletop and Diamond Clear Epoxy Casting. Our Diamond Clear Epoxies are self-leveling, primer-less, odorless, and always water-clear. They’re easy to apply using foam brushes, rollers, or squeegees.

To learn more about our line of Diamond Clear Epoxy, or to get started on your epoxy solution, contact us or request a quote today.

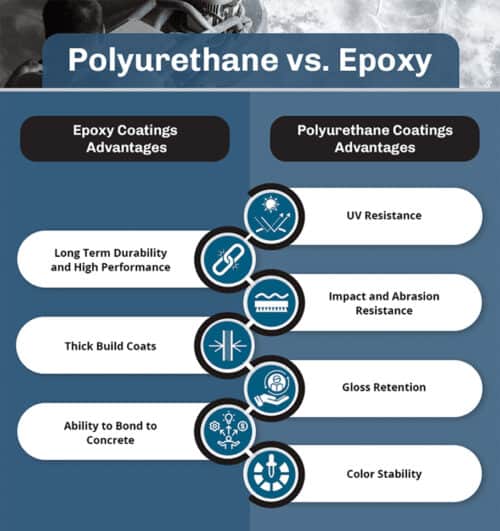

Whether you’re undertaking a DIY craft or home improvement project or overseeing a large commercial project, it’s important to understand the nuances between polyurethane and epoxy coatings. These two coatings may seem similar, but each has distinct properties and advantages tailored to specific needs.

There are many uses for epoxy and polyurethane coatings, and selecting the right coating is important for long-lasting protection and performance.

For example, consider a homeowner who is renovating their garage floor. They require a coating that can withstand frequent traffic, spills, and potential oil leaks. On the other hand, an industrial facility manager may be tasked with safeguarding concrete surfaces against corrosion, impact, and harsh chemicals.

In each scenario, the choice between polyurethane and epoxy coatings hinges on factors such as substrate type, project requirements, and environmental conditions. Learning the unique properties and advantages of each coating will help you choose the right solution for your project.

Let’s take a look at these popular coatings, starting with a clear definition of epoxy and polyurethane.

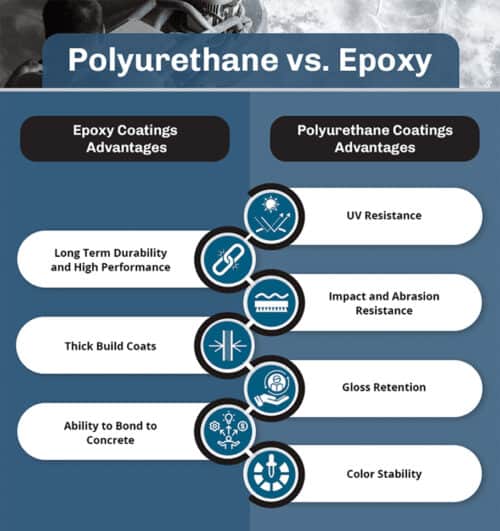

What is Epoxy?

Epoxy is a hard-wearing resin system known for its surface tolerance and adhesion to various substrates. It offers versatility with properties like chemical resistance or fast-setting. Depending on the intended application, you may choose any one of several epoxy options.

Here are some key advantages of epoxy coatings:

- Surface Tolerance: Epoxy coatings excel in adhering to different surfaces, making them ideal for a wide range of applications.

- Ability to Bond to Concrete: Epoxies can chemically and mechanically bond with concrete, making them a preferred choice for coating concrete substrates.

- Durability and Impact Resistance: Once treated with an epoxy resin, surfaces have a harder, more durable surface with impressive impact resistance.

- Thick Build Coats: Thanks to their thickness, epoxy coatings are able to self-level and create smooth surfaces by filling cracks and blemishes.

What is Polyurethane?

Polyurethane is a versatile polymer compound that is commonly used in various applications. It offers a softer alternative to epoxy with remarkable scratch resistance and flexibility, making it ideal for flexible substrates.

Here are some key advantages of polyurethane coatings:

- UV Resistance: Polyurethane coatings are highly resistant to UV radiation, making them suitable for outdoor applications.

- Impact and Abrasion Resistance: They offer excellent protection against impacts and abrasions, maintaining the integrity of the coated surface.

- Gloss Retention: Polyurethane coatings retain their glossy finish over time, enhancing the aesthetic of the coated surface.

- Color Stability: They also provide long-term color stability, ensuring the coated surface maintains its appearance.

Applications and Uses

Both epoxy and polyurethane coatings find applications in various industries and projects. Epoxy offers higher levels of rigidity and adhesion, making it suitable for harder surfaces, like concrete and areas with high physical impacts. Polyurethane, on the other hand, is often chosen for its cosmetic performance characteristics that offer holistic protection for the entire system.

Choosing the Right Coating

When selecting between epoxy and polyurethane for your project, consider the following factors:

- Surface Type: Determine the type of surface you’re coating. Epoxy is ideal for harder surfaces, while polyurethane is better suited for flexible surfaces.

- Project Requirements: Consider the specific needs of your project, such as durability, UV resistance, or aesthetic appeal.

- Cost Consideration: Polyurethane coatings may cost more upfront, but they can offer long-term savings in certain applications.

- Environmental Conditions: Think about the environmental factors your project will face, such as exposure to high traffic or harsh chemicals.

Understanding the unique properties and advantages of epoxy and polyurethane coatings will help you select the right solution for your next project. Whether you prioritize durability, flexibility, or aesthetic appeal, there’s a coating option that suits your needs.

Industrial Epoxy Solutions from Copps Industries

For applications that require significant durability and high performance, epoxy resins are the ideal choice. Since 1979, Copps Industries has been dedicated to providing the finest industrial epoxies in the field. Over decades of experience, we’ve successfully diversified our lineup to offer more than 500 products in 27 countries. Markets we serve include:

- Electronics

- Civil Engineering

- Structural Adhesives

- Aggregate/Mining

We’re dedicated to manufacturing products of the highest caliber at our ISO 9001:2015-certified facilities. Contact us or request a quote today and learn more about our epoxy resin solutions.

In the dynamic, demanding world of aggregate and mining, there’s zero time for unplanned equipment downtime. When it hits, production halts. Profitability crashes. And jobs can be at stake.

To help minimize the ripple effects of downtime, on-site managers and engineers alike count on crusher backing solutions from Copps. For over 45 years we’ve established a proven track record – as well as a trust – that once our solutions disappear into critical parts of a machine, they do what we promise: help keep operations online, on time, and equipment operating efficiently for longer. For anything that needs crushing, under the most extreme conditions, anywhere in the world. And it’s with the world in mind that we develop our products. Not just for the job at hand today, but with long-term implications in mind for your people and the environment as well. In fact, Copps is the only company to date to offer non-corrosive versions of standard and high-performance crusher backing options. We don’t just lead this market in environmentally conscious solutions – we are the market.

Raising the Bar for Your Toughest Jobs

While some well-known, established companies choose only to offer one type of backing product, our experience, expertise, and chemistry tell us that different materials and machines require different solutions.

That’s why we formulate and offer both standard as well as premier, high-performance versions of our products, designed specifically for your toughest jobs. All as we continue to lead the way in our commitment to the environment by offering eco-conscious versions of our crusher backing solutions.

Recommended for use in most (including severe) crushing applications. With uniform consistency, pourability, and cured toughness it offers elevated compressive strength, service temperature, and impact resistance. Does not contain VOCs, butyl glycidyl ether (BGE), or nonylphenol.

A DOT non-corrosive version of our standard backing formulated to address environmental, workplace safety, and shipping concerns. It provides the same support or “backup” for manganese steel or alloy wear parts in cone and gyratory crushers as our traditional material, and is butyl glycidyl ether (BGE), VOC, and nonyl phenol free!

The ultimate backing material for the toughest, most demanding crushing applications. Uniquely designed with extreme impact resistance, very low water absorption, and the ability to withstand hard or abrasive material and high-temperature crushing environments. Does not contain VOCs, butyl glycidyl ether (BGE), or nonylphenol.

The DOT non-corrosive version of our current ultimate backing material. Designed to engage the most challenging crushing conditions: gyrators, primary crushing, wet crushing, and hard or excessively abrasive media. Does not contain BGE, VOCs, or nonylphenol. It offers exceptional heat, water, and shrinkage resistance.

What Crusher Backing Compounds Do For You

The stresses your equipment faces day in and day out, hour after hour, are immense. Our crusher backing compounds help protect it all from unnecessary damage and assist in long-term wear by filling the open cavities behind wear parts and supporting crushing wear surfaces. In doing so, our compounds help to minimize the effect of friction, vibration, and impact on the machinery during crushing operations. They offer a range of benefits for mining and aggregate operations including:

Extended Machinery Life

Applying crusher backing compounds on an appropriate maintenance schedule substantially extends the life of equipment and related components, minimizes downtime, and lowers replacement part costs.

Low Shrinkage

Using a properly formulated crusher backing compound engineered to manage shrinkage during the hardening or curing stage greatly reduces the risk of voids and misalignments between liners.

High Strength

Our compounds offer a higher level of compressive strength, a broader array of service temperatures, and higher impact and vibration resistance to improve component and machine efficiency and durability.

Gap Elimination

Eliminating wear liner gaps and smoothing alignment errors provides equipment with superior impact resistance compared to equipment not treated with a crusher backing compound.

Performance, Profitability, and More.

Across the US and around the world, mining companies today are coming under scrutiny. While keeping up performance and remaining profitable will always be job number one, mining leaders are being asked to do more than ever. Like enhancing commitments to the environment and making conscious efforts to improve workforce health and safety.

With the crusher backing solutions offered by Copps on-site and at the ready, you can do both.

To learn more about our crusher backing compounds or other epoxy-based solutions, contact us or request a quote.

Put the power and innovation of Copps Industries to work for you today. From our commitment to the environment and sustainability to our private label offerings and “virtual chemist” opportunities, we’re ready to help create better solutions for you.

Page 4 of 6« First«...23456»