Stronger yet lighter weight. More flexible yet more durable. Thermally insulated. Versatile. And chemical or corrosion-resistant on top of it all. If the part or component you need must be some, all, or even more of these, your best solution is an epoxy composite.

If you need it fast and done to your exacting standards, the only solution is to partner with Copps.

Here, collaboration with our customers is king. Short lead times and fast turnarounds are to be expected. And access to our entire team, from service to formulation, to support after you have what you need – is guaranteed.

And because we service a wide range of markets outside of the epoxy composites world, we’re able to connect you with different expert perspectives and new ideas. The kind other sources simply can’t provide.

Reinforcements: Putting it All Together

Your job, your product, your needs are unique. What’s not unique is the fact that epoxy resin alone typically doesn’t provide enough structural integrity to meet the reliability and durability you need.

We cater our epoxy development to create a low-density material with a high strength-to-weight ratio to meet the needs of diverse applications specifically with each of these types of reinforcements:

- Carbon fiber

- Fiberglass

- Aramid

- Natural fibers: jute, flax, and kenaf

- Exotic fibers: boron, basalt

- Particulate fillers: ceramic, silica, metal

Properties and Advantages of Different Reinforcements

Each reinforcement material offers its own unique characteristics and benefits. The best material for your specific application depends on its intended use. Some of the most common properties reinforcements offer include:

- Impact resistance

- Stiffness

- High strength-to-weight ratio

Not Just a Manufacturing Process. Your Process.

For every type of process, there’s a set of variables that come into play – as well as the desired outcome. That’s why we develop products not just for the process type, but for the individual customer variation within each process type. That’s what makes Copps unique.

Through customer collaboration, meticulous attention to detail and precision, we develop products for all of these processes:

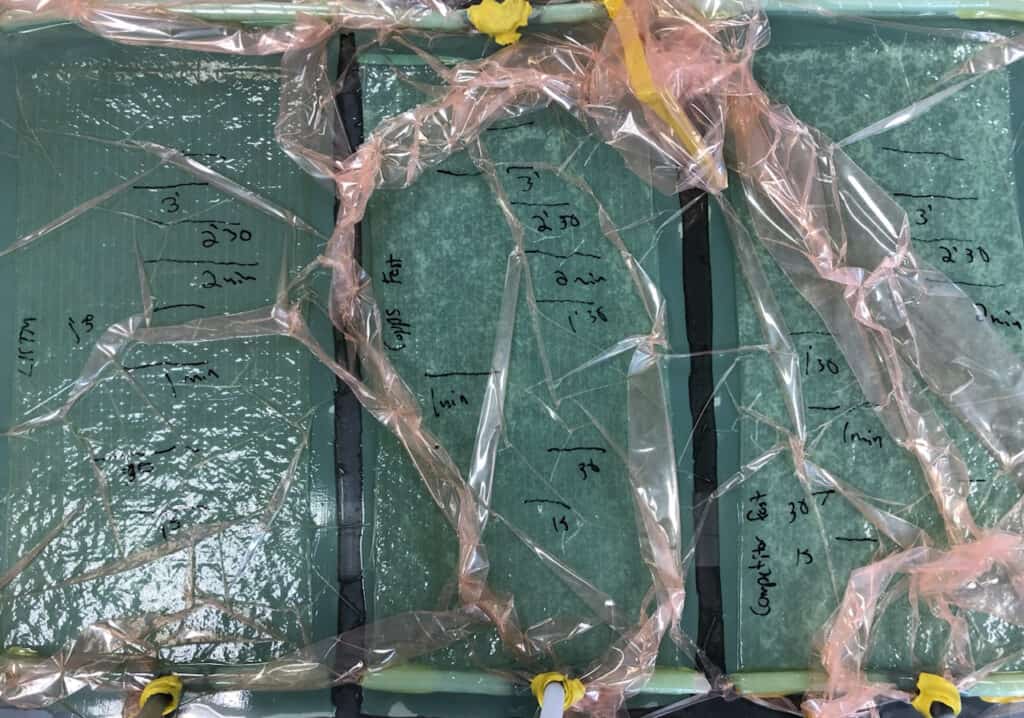

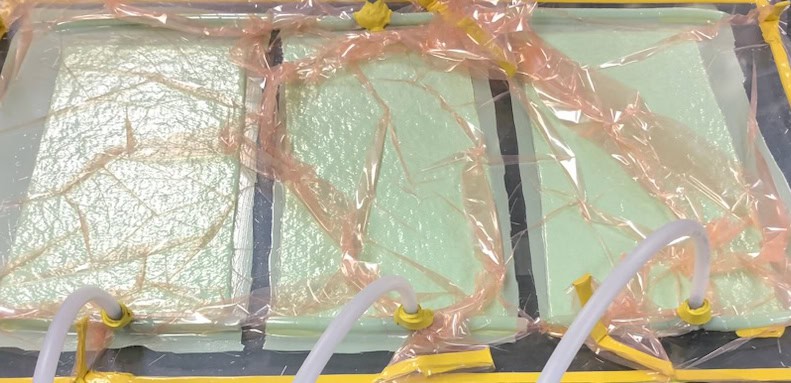

- Vacuum Bagging: An open molding technique (including Wet Bagging) that places mechanical pressure on a laminate during its cure cycle. Designed to achieve higher-than-normal properties of Hand Layup without the technical challenges of VIP.

- Hand Layup: The simplest composite molding method available where fiber reinforcements are wet out by hand and manually positioned into a mold.

- High-Pressure Resin Transfer Molding (HPRTM): Rapidly becoming popular in the automotive, industrial, and agricultural industries, this is a high-output process where dry reinforcement fabrics are placed into metal tooling inside of a high-tonnage hydraulic press. Resin is then injected under very high pressures for precise part geometry and repeatability. It can also be automated in a 5-step process.

- Light Resin Transfer Molding (LRTM): A closed-mold process similar to resin transfer molding where both the A and B molds are made of composites. This technology is frequently applied in production of boats and water equipment but has infinite possibilities beyond, including car body elements, trailers, aircraft, and more.

- Vacuum Assisted Resin Transfer Molding Process (VTRM): Another variation of RTM, this too is a closed-mold manufacturing process. Unlike LRTM, the top portion of a mold tool is replaced with a flexible vacuum bag, and vacuum only, no injection, is used to assist in resin flow. Currently most used in composite production where only one part of the laminate is visible.

- Vacuum Infusion Process (VIP): A low production-level, closed-mold process with a single-sided tool that is loaded with dry fabrics. A flexible film is then used to apply full vacuum to the part and the resin is drawn into the reinforcement through the vacuum applied. Popular infusion resin types include epoxy, polyester, and vinyl ester.

- Filament Winding: The process of winding resin-impregnated strands of fiber around a rotating mandrel to create a composite structure. Creates high-fiber loading with good directional strength for extremely strong composite products.

- Pultrusion: A high throughput process for making straight solid shapes where dry fibers are dipped in resin and pulled through a heated metal die creating the part profile and curing in one step. Best suited for high-volume, single-direction reinforced products like rods, poles, trim, flat panels, and more.

Regardless of the method to suit your process, our quality control and testing are vital to ensure the final product will meet the required standards.

Markets Served by Our Epoxy Composites

Where in the real world will you find epoxy composite solutions from Copps?

Virtually anywhere. By land, sea, and air (even above and beyond) Epoxy composites are used throughout nearly every industry.

In the automotive sector, they help create vehicle parts for increased performance and weight reduction. Composites can be used to form structural components in the construction industry. The marine industry relies on them to manufacture boat hulls, decks, consoles, and hatches. In aerospace, they’re a popular choice for aircraft components thanks to their lightweight nature and strength. Here are just some of the markets we’re currently serving:

- Aerospace

- Marine

- Construction

- DoD

- Industrial

- Motorsport

- Automotive

- Sports & Leisure

Exceeding Your Epoxy Composite Expectations

If you have an epoxy composite need or challenge, call on Copps Industries. We’ll create a solution you can have confidence in. Performance and reliability can’t be topped by the day-in and day-out experience you’ll have working with our team of experts. When you’re ready to get started on your next, best composite, contact us today.

Request Quote

Request Quote