Although many people use the terms polyurethane and epoxy interchangeably, they are actually two distinct types of coating with their own properties and advantages. As they are both hardwearing resin systems, each one functions well in busy plants or other facilities where physical impacts are common. However, with such a wide range of polyurethane and epoxy options to choose from, it may be challenging to find the best option for a given application. By understanding the differences between each one, you’ll easily be able to make a decision.

Although many people use the terms polyurethane and epoxy interchangeably, they are actually two distinct types of coating with their own properties and advantages. As they are both hardwearing resin systems, each one functions well in busy plants or other facilities where physical impacts are common. However, with such a wide range of polyurethane and epoxy options to choose from, it may be challenging to find the best option for a given application. By understanding the differences between each one, you’ll easily be able to make a decision.

Epoxy Coatings

A major advantage of epoxies is their surface tolerance, as they can adhere extremely well to a variety of substrates. Depending on the intended application, manufacturers may choose any one of a number of epoxy options, each with its own specific properties. For example, an epoxy may be chemical resistant or fast setting.

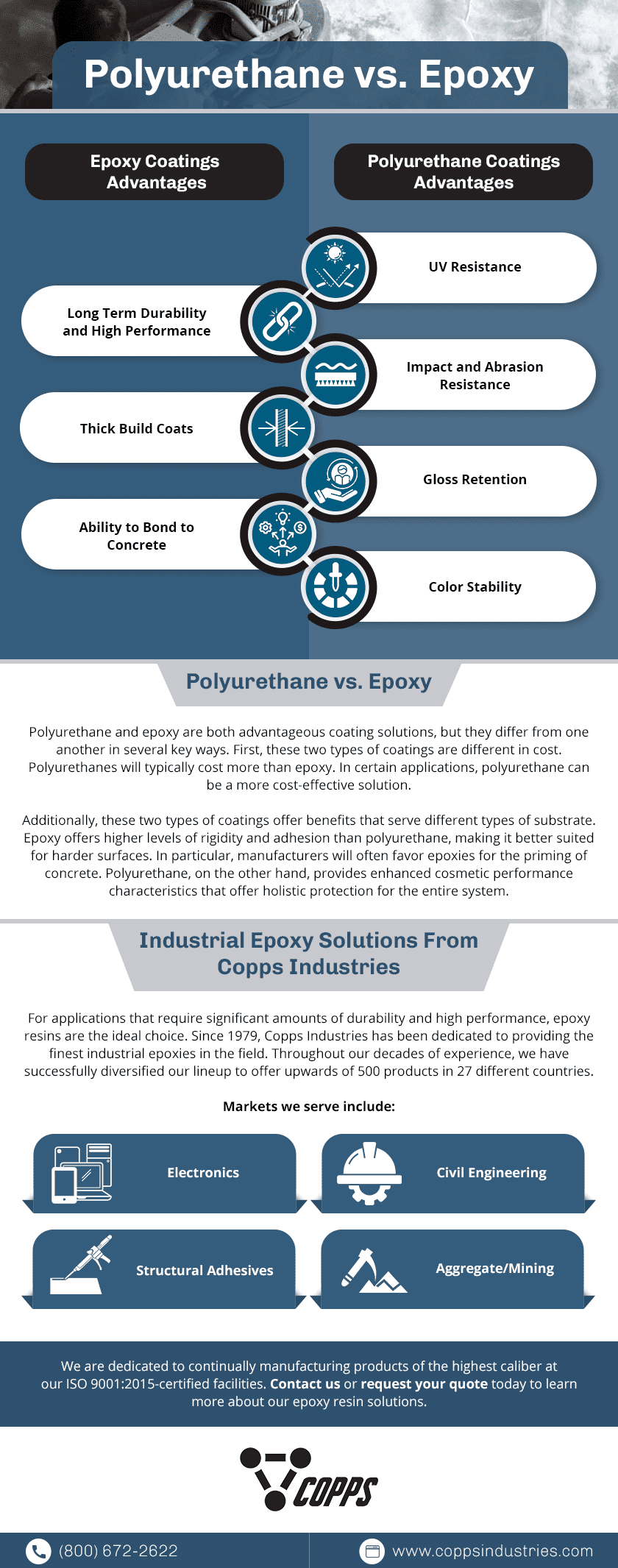

Regardless of the specific epoxy, in general, this type of coating offers impressive amounts of durability and impact resistance, making it an ideal choice for either a primer/intermediate coat or a topcoat. Epoxies also offer the following significant benefits:

- Ability to Bond To Concrete: In situations where a concrete substrate must receive a coating, epoxies can bind with it both chemically and mechanically.

- Thick Build Coats: Thanks to their thickness, epoxy build coats are able to be self-level, and can create smooth surfaces by filling cracks and other small blemishes.

- Long Term Durability and High Performance: Once treated with an epoxy resin, substrates will have a harder, more durable surface that provides good impact resistance.

Polyurethane Coatings

While epoxy coatings are hard and offer high amounts of impact resistance, polyurethane provides a softer option. It is more scratch-resistant and ideal for flexible substrates. Polyurethane’s flexibility also helps prevent concrete cracks from moving through the coating. Polyurethane has numerous advantages despite its thinner build coats, including:

- UV Resistance

- Impact and Abrasion Resistance

- Gloss Retention

- Color Stability

Polyurethane vs. Epoxy

Polyurethane and epoxy are both advantageous coating solutions, but they differ from one another in several key ways. First, these two types of coatings are different in cost. Polyurethanes will typically cost more than epoxy. In certain applications, polyurethane can be a more cost-effective solution.

Additionally, these two types of coatings offer benefits that serve different types of substrate. Epoxy offers higher levels of rigidity and adhesion than polyurethane, making it better suited for harder surfaces. In particular, manufacturers will often favor epoxies for the priming of concrete. Polyurethane, on the other hand, provides enhanced cosmetic performance characteristics that offer holistic protection for the entire system.

Industrial Epoxy Solutions From Copps Industries

For applications that require significant amounts of durability and high performance, epoxy resins are the ideal choice. Since 1979, Copps Industries has been dedicated to providing the finest industrial epoxies in the field. Throughout our decades of experience, we have successfully diversified our lineup to offer upwards of 500 products in 27 different countries. Markets we serve include:

- Electronics

- Civil Engineering

- Structural Adhesives

- Aggregate/Mining

We are dedicated to continually manufacturing products of the highest caliber at our ISO 9001:2015-certified facilities. Contact us or request your quote today to learn more about our epoxy resin solutions.

Request Quote

Request Quote